CO2 Blast Freezers for UK food-processing company

In 2020 we installed a new CO2-based cooling plant at a food processing company in the United Kingdom.

The brief was to design and supply a 180 kW cooling capacity plant, for low temperature blast chilling of meat in six identical cooling chambers for an air temperature requirement of -20° C.

For the customer, the choice of CO2 was motivated by price, which was a major factor, along with the desire for future-proof technology.

Above: The six blast chill cabinets

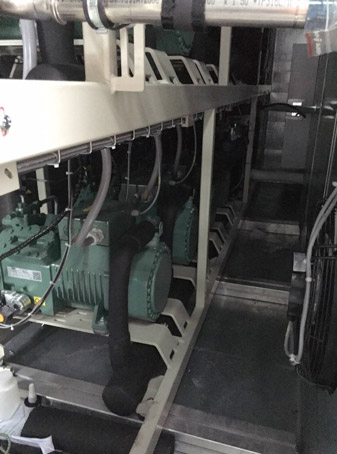

Above: The CO2 housed unit pack with

gas cooler and de-superheater cooler

Options considered

We initially considered an ammonia-based pumped recirculation system. But this was subsequently ruled out due to price, space, delivery time and specific site safety considerations.

Another option would have been to use a direct expansion system with HFC R407F. The customer ruled this out amid the imminent phase-out restrictions which could render the investment negatively, as well as the rising price of the refrigerant considering the volume required, which was approximately 500kg.

A pumped system with CO2 was initially considered but this meant the additional cost of a low-pressure pumping station vessel and skid would mean a significantly higher cost over that of the HFC system. It would also have required a large footprint requirement for the plant, for which space was not available.

This is a title Case Study – Test

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Delivered Solution

The system chosen is a direct expansion system with approximately 300 kg of CO2 R744 refrigerant inside it.

The freezer suction line pressure is typically around 15 bar and the average freezer liquid line pressure is approximately 25 bar.

Thus far the system’s operation has exceeded our expectations in performance and reliability and we look forward to receiving more operational data in due course.

Above: Inside the weatherproof compressor enclosure

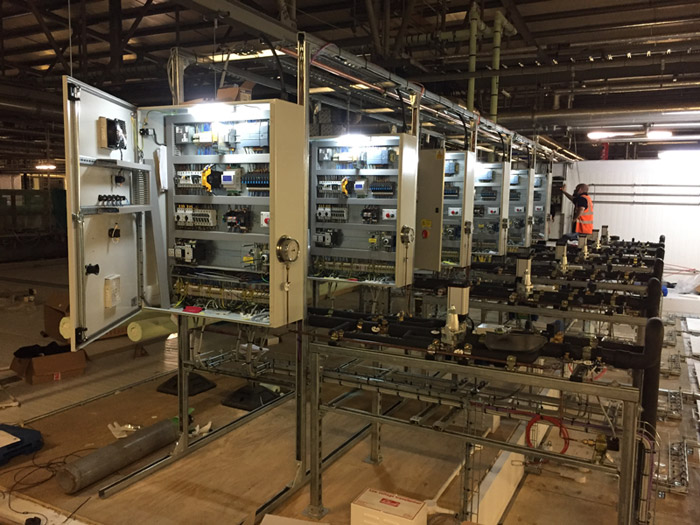

Above: Construction of the CO2 plant