Custom Refrigerated Trailers

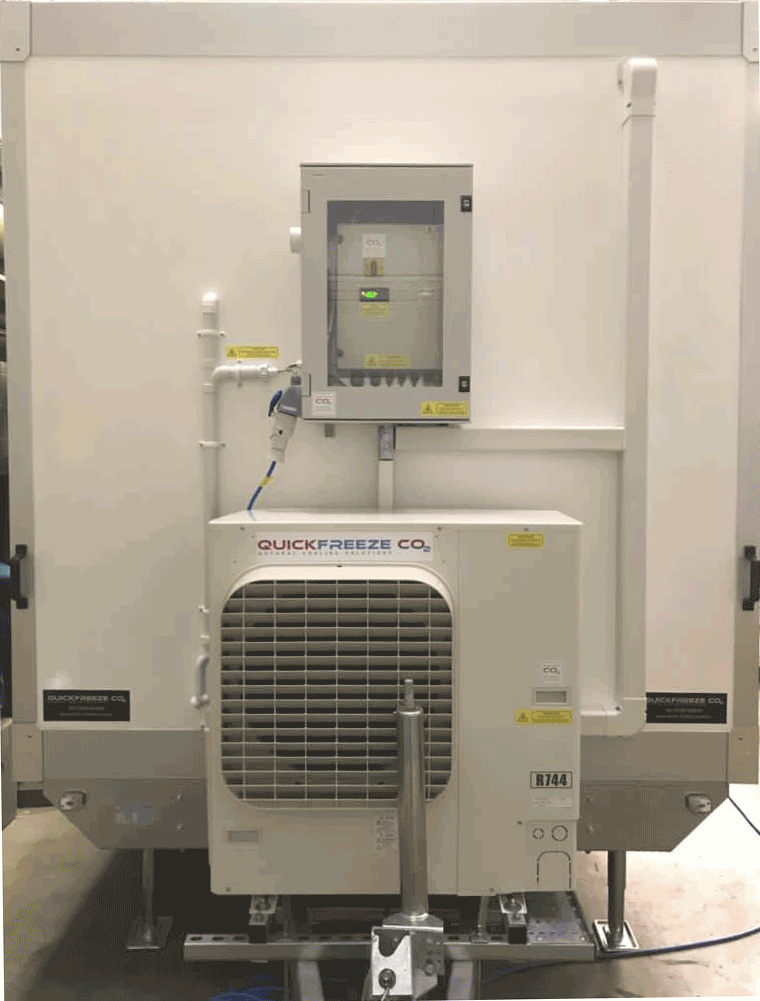

We specialise in building custom CO₂ refrigeration trailers for the industrial, commercial and public sectors. We also have trailers for hire.

The trailers provide a holding fridge or freezer which can be located indoors or outdoors and has the option of being more easily relocated than static coldrooms.

Our trailers are perfect for eco-conscious customers who want to make the right choice for the environment. They use a transcritical system which can provide chilling or freezing, to suit your application, which is cost-effective in all climates.

Above: Inside a small refrigerated trailer

Versatile

We are the first company in the UK building towable CO₂ refrigerated trailers as well as offering them for hire. Our trailers avoid the previous logistic challenges of delivering a refrigeration solution via an articulated lorry, which is not always convenient for your intended location.

Our trailer will be conveniently delivered to your site, positioned and commissioned by our refrigeration engineer – indoors or outdoors – with minimum fuss.

Chill or Freeze

Our trailers are versatile and can be set up to run in a chill or freeze condition, as per your requirements. There are many potential uses for our trailers, which include:

- Caterers, Hotels & Restaurants

- Corporate Hospitality

- Festivals, Music and Sporting events

- Weddings and Parties

- Markets & Pop-Up Stalls

- Emergency Backup for Food Factories, Restaurants, Medical & Pharmaceutical companies

Why choose a CO₂ trailer?

CO₂ is a natural refrigeration solution, and we believe is the future for this sector. It is more efficient to run, and certainly more environmentally friendly than the more conventional refrigerated trailers which commonly run on HFC gases.

CO₂ has a very low GWP (global warming potential) value of 1 as opposed to the current refrigerant typically used such as R404A having a GWP equal to 3800. With refrigeration legislation increasing over the coming years, HFC R404A will be out of circulation by 2020.

We believe people want to make an eco-conscious choice for cooling their products but it’s an economical one too: Higher efficiency means less power is required, and therefore lower running costs.

Minimise your carbon footprint by lowering CO₂ emissions. Read more about why you should choose CO₂ for your cooling.

Trailer Energy Efficiency

Based on the manufacturer’s monitored data, 16% energy savings for chilled refrigeration and 25% energy savings for lower temperature freezer applications have been achieved in comparison to R404A (Monitored within a 5°C to 27°C ambient 12-month operating period).

Above: Inside an empty large trailer

Trailer Specifications

Our trailers run from a standard 240 volt 13amp or a 16amp power supply and can be safely operated up to 25 metres from the power source.

The trailers have a 4 kW cooling capacity for Chill and 2 kW cooling capacity for Freeze applications. They come with internal lighting and can be configured with or without shelving, depending on your requirements.

The cold chain units exhibit very low noise levels, ranging from 35.5dB(A) to 36dB(A).

Large Trailers

Our large trailers can accommodate 5 standard UK size pallets or dolavs end to end (1200 mm x 1000 mm). Total payload is 2500 kilograms.

Interior floor space without shelving is 11.9 square metres (5860mm long x 2030mm wide x 2000 mm high).

Small Trailers

Our small trailers can accommodate 3 standard UK size pallets or dolavs end to end (1200 mm x 1000 mm). Total payload is 1840 kilograms.

Interior floor space without shelving is 4.95 square metres (3370mm long x 1470mm wide x 2000 mm high).

Operating Conditions

Typical operating conditions when the trailer is commissioned in a freeze configuration:

- Test Pressure: 90 Bar for 6 hours

- Vacuum achieved: 2 Torr for 1 hours

- Refrigerant charge: 2.14 kg R744

- Liquid line size: ¼” CU copper

- Suction line size: ½” CU copper

- Trailer internal room temperature set point: -20oC

- Saturated evaporating temperature: -28 oC

- Superheated gas temperature: -18.2 oC

- Superheat reading: 9.8K

- Discharge Pressure: 53.6 Bar

- Suction Pressure: 12.4 Bar

- Defrost: Electric 4 defrosts every 6 hours

Interested?

Please contact us to discuss your requirements!

UK PATENT APPLICATION NUMBER 1915236.2